UREA COATING SYSTEM

The urea coating system incorporates polyurea and hybrid coatings,

offering excellent waterproofing, anti-corrosion, abrasion resistance,

decorative performance, and ultra-fast application.

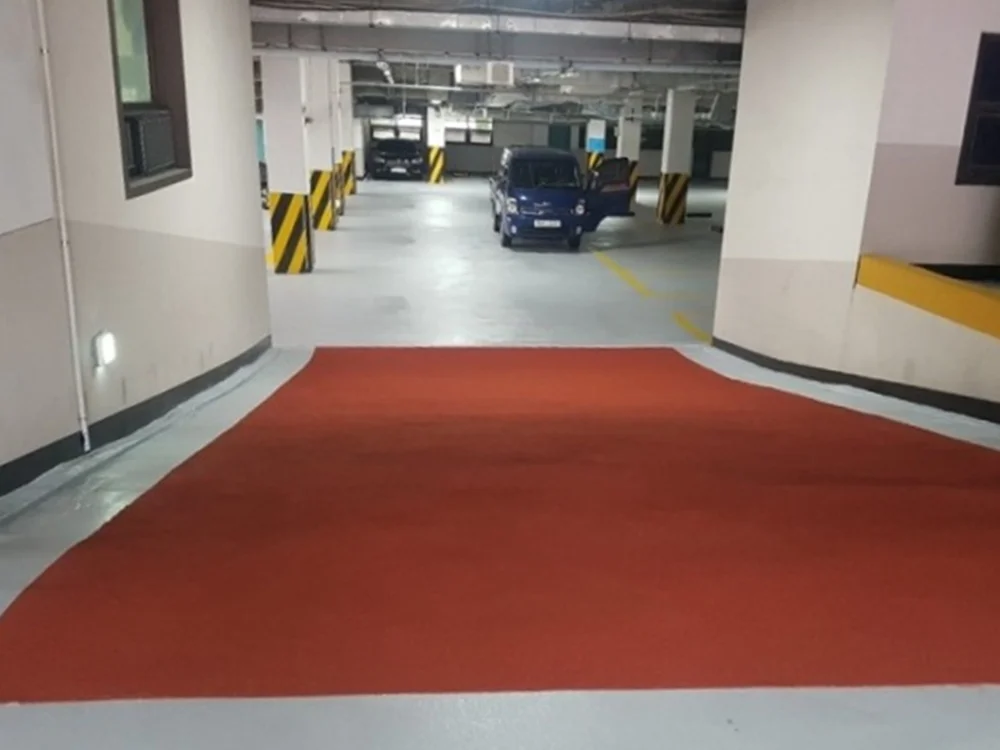

Indoor Parking Garage

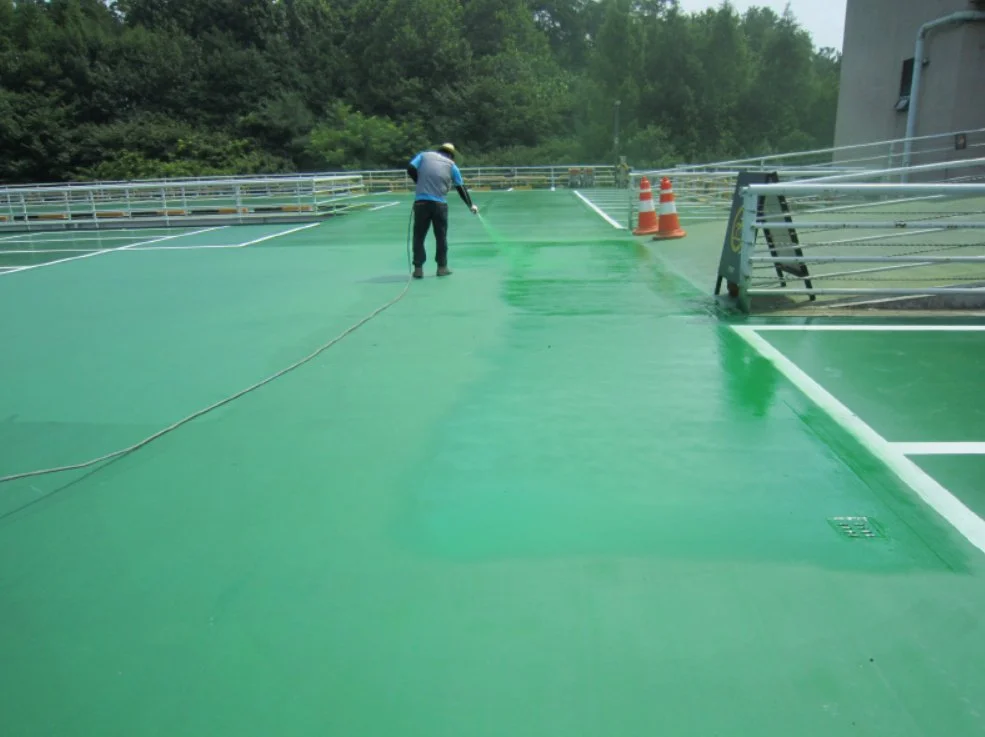

Outdoor Parking Garage

Water Park

Rooftop Waterproofing

Structural Installation

Steel Pipe Coating

Overview

The urea coating system is a two-component product available in both polyurea coating and hybrid coating options.

As an industrial coating material, it can be applied in diverse environments, offering excellent durability and rapid curing properties.

Key Features

Multi-purpose

Coating

Anti-corrosion, waterproofing,

abrasion resistance & decorative

Strong

Adhesion

Powerful bonding strength

with excellent smoothness

Seamless

Application

Joint-free installation

maximizes functionality

Ultra-fast

Curing

Ultra-fast curing

(4-6 sec gel time, tack-free ≤10 sec)

Application

Anti-Corrosion

Waterproofing

Durability

Adhesion

Decorative

Finishing

Products

| Product | Product Name | Usage | Hardness (Shore A) | Remarks |

|---|---|---|---|---|

| PURE POLYUREA COAT | UA-1001 | General purpose | 95 | Certified for KC, KS |

| UA-3005 | Buoy | 95 | Smooth surface using spatula | |

| UA-35TR | Anti-corrosion | 60 (Shore D) | High tensile strength | |

| UA-2000 | Urea Rolling | 95 | Urea brush grade | |

| HYBRID COAT | PK-410 | Parking Lot, Anti-corrosion | 95 | High hardness |

| EPL-400 | General purpose | 90 | Exposed/non-exposed waterproofing | |

| EPL-550 | Waterproofing | 85 | Top selling item | |

| EPL-700 | Waterproofing | 70 | High elongation | |

| EPL-810 | Waterproofing | 60 | High elongation | |

| PRIMER | PM-3 | Concrete | 1 Component | General |

| NK Safety Primer | Concrete | 2 Component | Less Pinhole | |

| NK Primer Coat | Concrete | 2 Component | VOC free | |

| PM-21 | Steel | 2 Component | High performance | |

| INTERMEDIATE POLYURETHANE | SL-60 | Surface preparation | 60 | Manual application |

| TOP COAT | TP-200 | Rolling, Spray | - | UV resistant (Glossy) |

Application Guide

| Use by sector | UA-1001 | PK-410 | EPL-550 | TP-200 | PM-3 | NK Safety Primer | PM-21 |

|---|---|---|---|---|---|---|---|

| Bridge surface | R | S | S | R | S | R | R |

| Potable water system | S | R | R | S | S | ||

| Water or Gas storage tank outside | S | R | R | S | S | R | S |

| Water or Gas storage tank inside | S | R | R | S | S | ||

| Inside and outside piping | S | R | S | S | |||

| Offshore Facilities | S | R | S | S | R | ||

| Roof | S | S | S | R | R | ||

| Waste water treatment plant | S | S | |||||

| Manholes and Sewer pipe | S | S | S | S | |||

| Theme Park and Decorative Design | S | R | R | S | S | ||

| Facility Floor, Parking Lot Floor | S | R | R | R | |||

| Aquarium | S | S | R | R | S | ||

| Landscape and water quality protection | S | R | S | S | |||

| Artistic design structures | S | S | S | ||||

| Water park | S | R | R | R | R | ||

| Train and Track Protection | S | R | R | S | |||

| Coastal facilities | S | R | R | S | S | S | |

| Crude oil, Waste oil pipe, processing facilities | S | R | S | S | |||

| Nuclear fuel storage | S | R | S | ||||

| Paper and pulp manufactory | S | R | S | S | S | ||

| Food processing plant | S | R | S | S | S | ||

| Canal, dam, storage facilities | S | R | S | R | |||

| Storage facility | S | R | S | S | |||

| Refrigeration built-in equipment | R | R | S | ||||

| Industrial and production facilities | S | R | S | S | S | S | |

| Steel structures | S | R | S | R | S | ||

| Chemical plant | R | R | R | S | S | R | |

| Power plant | S | R | R | R | R | R | |

| Landfill | S | S | R | R | S |

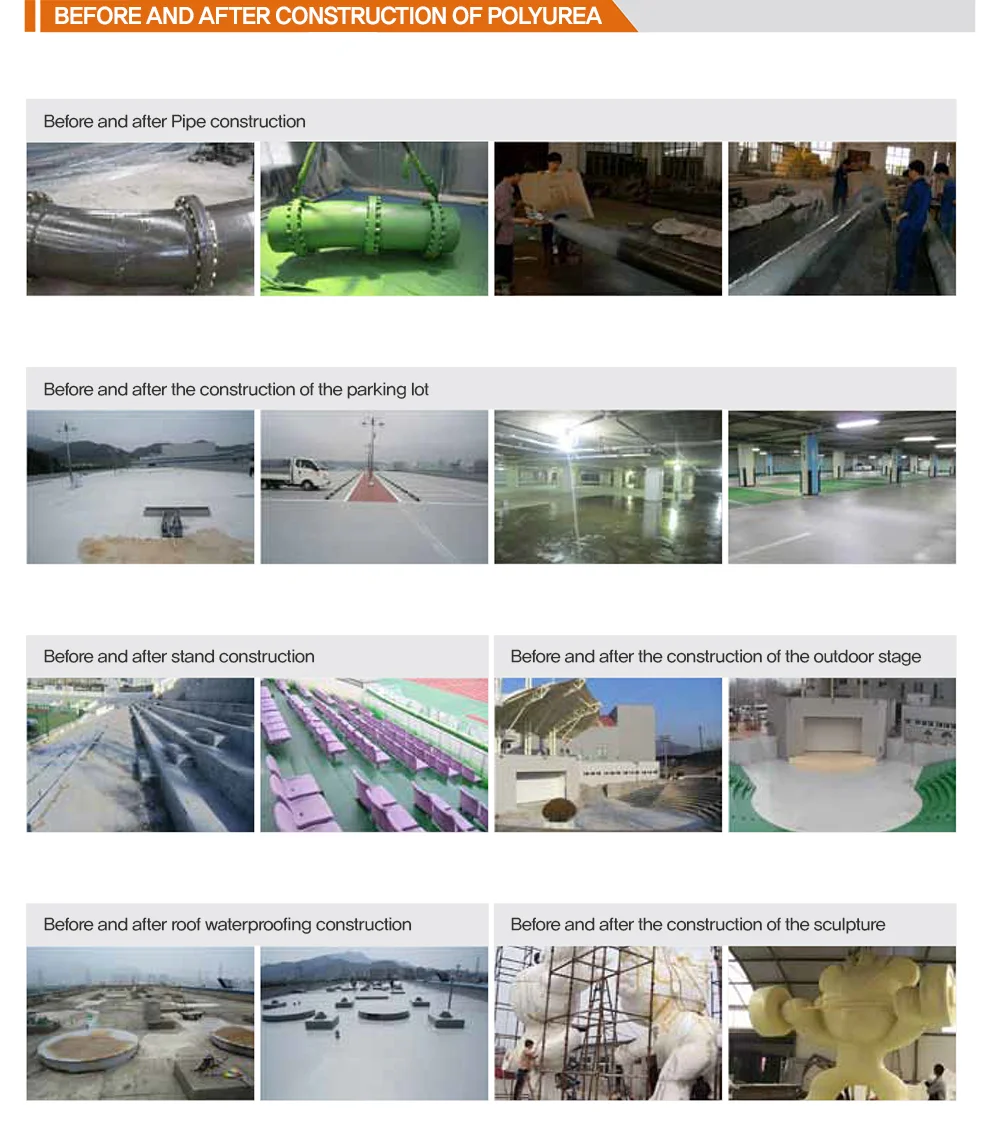

View Polyurea Before & After Photos

Recommended Application System

General specification

NK Safety Primer specification

Steel coating specification

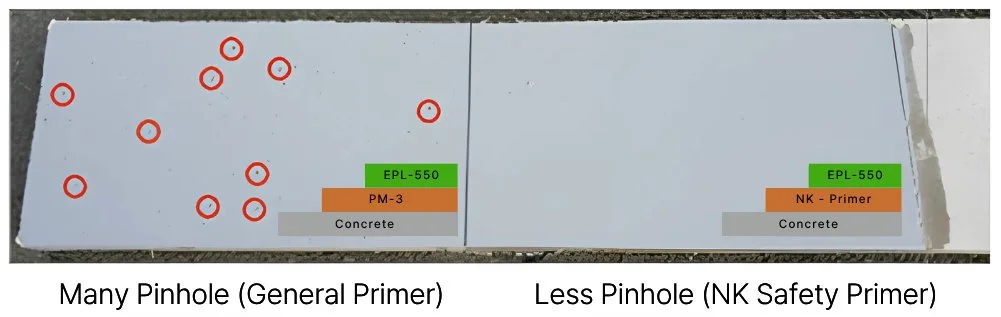

NK Safety Primer Features

Pinhole Prevention

Developed as a dedicated primer for polyurea, it significantly reduces pinhole formation during application

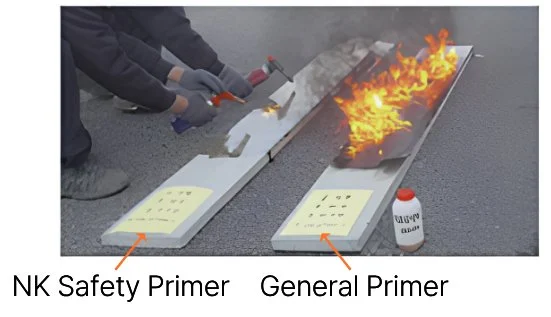

Fire Resistance

With reduced flammability during primer application, it offers improved fire safety compared to conventional products, even in confined spaces

Application Efficiency

With fast curing that reduces pinhole formation, it can shorten the overall construction period by approximately half

Pinhole Prevention Effect

General primer vs NK Safety primer

Pinhole formation comparison

Fire Safety

NK Safety primer and general primer

fire safety test

Application Method

NK Safety Primer Application Guide

This two-component urethane primer is fast-curing and

must be applied with polyurea spraying equipment

Usage

0.2 ~ 0.45kg/m²

Primer Recoat Time

30 ~ 60 minutes

Project Completed in Just 7 Hours

Surface Preparation

1st Primer Application (0.15mm)

2nd Primer Application (0.25mm)

Polyurea Application

Completed in just 7 hours (10 PM – 5 AM)

(Primer recoat time: 30–60 minutes)

Product & Application Inquiry

Technical review and guidance on products and systems

based on your application requirements.